Coaxial Connectors: Types, Structure, and Uses Explained

What Are Coaxial Connectors?

A coaxial connector connects a coaxial cable to a device. It's used for high-frequency products. The connector shape follows international standards, so different manufacturers can use the same type. The connection has a male (plug) and female (jack) part.

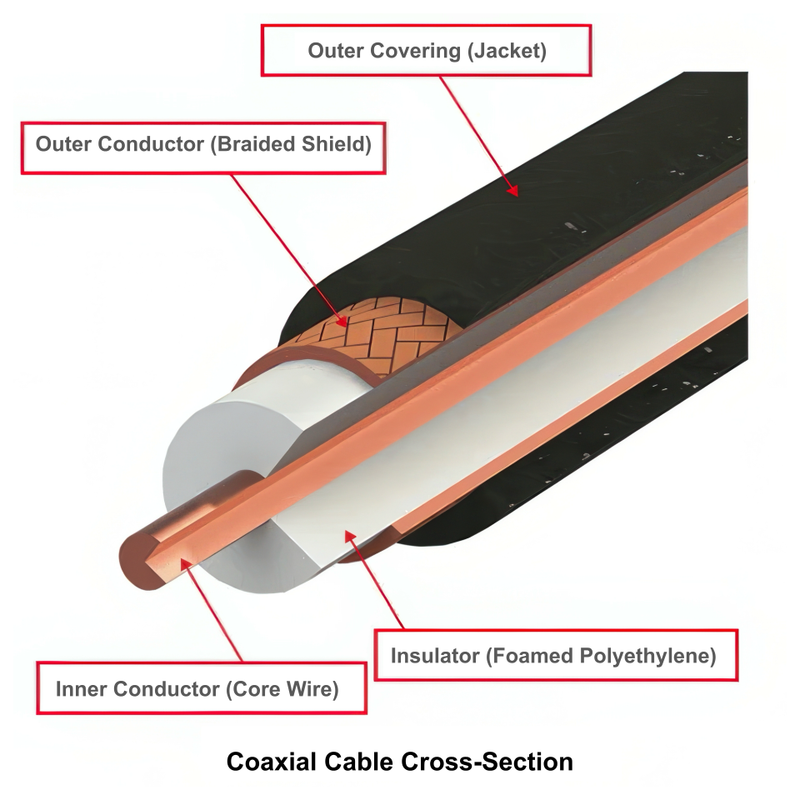

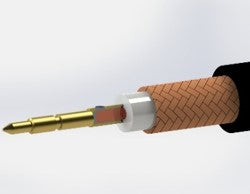

What Are Coaxial Cables?

Coaxial cable is a type of sheathed wire used in telecommunications for high-frequency signals. It has an unbalanced connection, minimal electromagnetic wave leakage, and some flexibility. If the characteristic impedance isn't specified, it may be called "shielded wire" instead of "coaxial cable." Various connectors are used with coaxial cables, depending on the frequency and impedance characteristics.

Installing Cables and Connectors

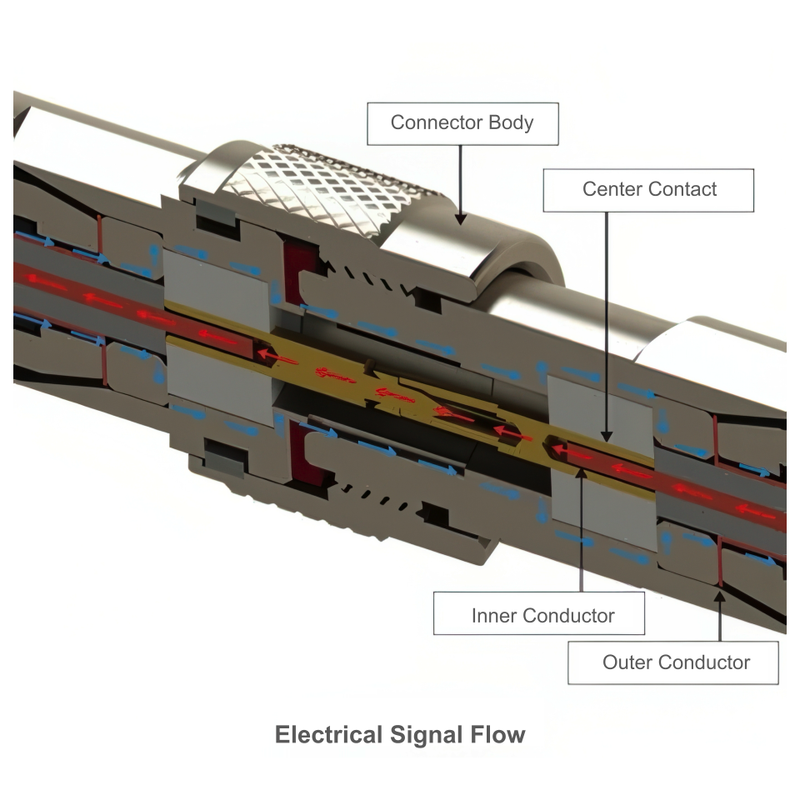

Coaxial connectors facilitate signal transmission by securely attaching plugs or jacks to coaxial cables, ensuring reliable connections for various applications.

Electrical signals flow when the contacts are in close contact with each other and with the body. Please refer to the “Cable Installation Diagram” on the datasheets of all applicable products for the cable installation method.

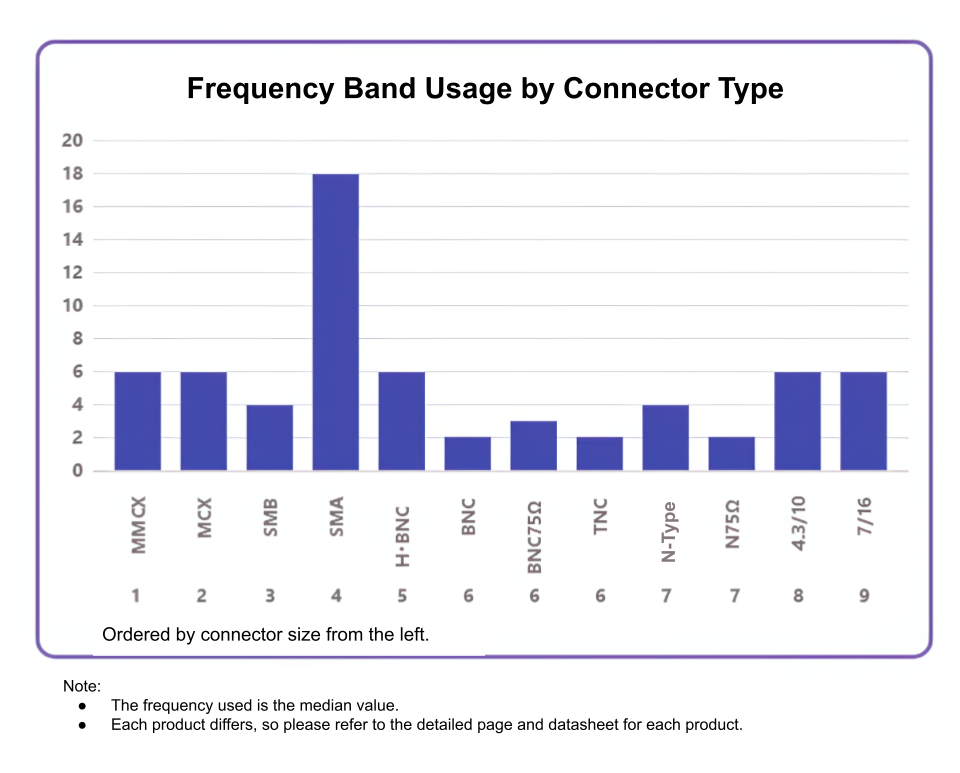

Frequency Bands of Coaxial Connectors

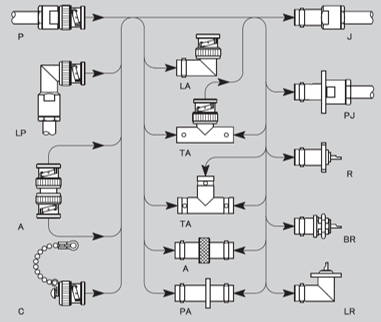

Functional Classification of Coaxial Connectors

Plug (P)

Jack (J)

Receptacle (R)

Adapter (A)

Functional Classification

Connecting the center contacts of the male and female openings is called 'mating.' The mating combinations for each functional classification are as follows.

Center Contact of Coaxial Connectors

Male center contacts are used for male openings, while female center contacts are used for female openings. The center contact of both the plug and jack is either soldered or crimped to the core wire of the coaxial cable in some products.

Solder the Center Contact and Cable Core (Male)

Solder the Center Contact and Cable Core (Female)

Crimp the Center Contact and Cable Core (Male)

Crimp the Center Contact and Cable Core (Female)

Trivia: What is a Reverse Type?

In some wireless communication systems, a "reverse type" connector is used, where the roles of male and female contacts are swapped compared to standard configurations. Specifically, the female contacts are used as plugs, and the male contacts serve as jacks.

This reversal is seen in certain specialized equipment, primarily overseas, and is designed for particular technical requirements. Understanding this distinction is important for ensuring compatibility between connectors in reverse-type systems.

Coaxial Connector Shapes and Their Functions

At Tyclon, we offer a diverse range of coaxial connectors, each designed with a specific function in mind. These connectors come in various shapes to accommodate different equipment setups, cable placements, and installation requirements. Below, you'll find a selection of commonly used connector shapes, each tailored to provide optimal performance in specific applications.

Straight

Right Angle

Bulkhead Jack

Flange Jack

Flange Adaptor

Terminator

Methods for Attaching Coaxial Connectors

There are three primary methods for attaching coaxial connectors to cables.

Tightening

This method utilizes a connector body typically consisting of a shell and a clamp. After the cable is inserted into the connector body, the clamp is tightened securely around the cable, usually with a wrench.

- Requires no specialized tools beyond a standard wrench.

- Generally provides a secure and reliable connection. Often suitable for field repairs as it may be disassembled.

- Typically more expensive than crimp-style connectors.

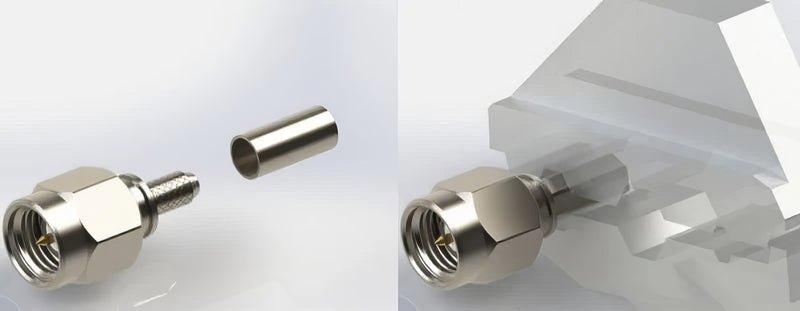

Crimping

Crimping involves a connector body, commonly comprising a shell and a separate ferrule (or sleeve). Once the cable is prepared and inserted, a dedicated crimping tool is used to compress the ferrule uniformly around the cable, securing it both mechanically and electrically.

- Generally less expensive than tightening or compression connectors.

- Offers a relatively quick and straightforward connection process when using the correct tool.

- Requires a specific crimping tool designed for the particular connector and cable size.

- Connection integrity depends heavily on using the correct tool and proper technique; an improper crimp can lead to poor performance or mechanical failure.

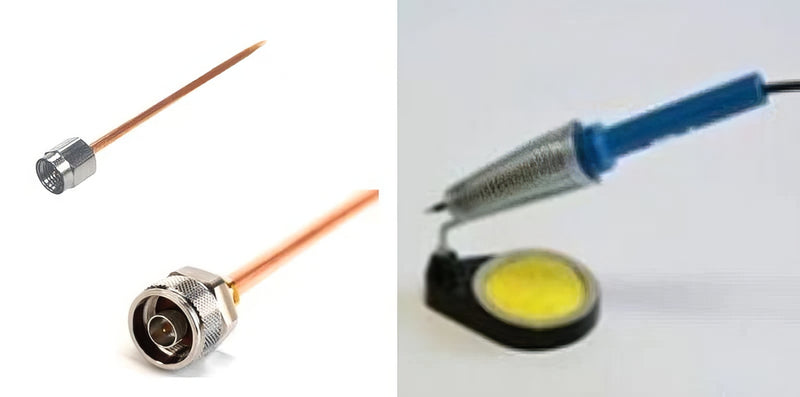

Soldering

Soldering creates a permanent electrical and mechanical bond by melting solder alloy to join the cable's conductor and shield to the connector components. This method is primarily used for attaching connectors to semi-rigid and semi-flexible coaxial cables, rather than standard flexible types.

Application Examples of Coaxial Connectors

Coaxial connectors are essential components used to establish reliable connections between coaxial cables and devices. The examples below illustrate common applications for various connector types.

When selecting a connector, always consider the specific requirements of your application, including device size, installation environment, and the required operating frequency range.

TV Antenna / TV

Video / Surveillance Camera

Disaster Prevention Radio

Mobile Communication Base Station

- 7/16 Connectors

- NXT Connectors

Wireless Communication Equipment / Measuring Instruments

- TNC Connectors

- SMA Connectors

LTE Router / Small Communication Device

- SMB Connectors

- MCX Connectors

- MMCX Connectors

Amateur Radio Equipment

Coaxial Connector FAQs

QWhat is a coaxial connector?

QWhat is a coaxial connector?

A coaxial connector links a coaxial cable to a device, enabling high-frequency signal transmission.

QHow do coaxial connectors differ from coaxial cables?

QHow do coaxial connectors differ from coaxial cables?

Connectors join cables to devices, while cables carry signals. Both are essential for high-frequency applications.

QWhat are the main types of coaxial connectors?

QWhat are the main types of coaxial connectors?

Common types include BNC, SMA, TNC, F, N, and HN connectors, each suited for specific applications.

QWhat is the significance of impedance in connectors?

QWhat is the significance of impedance in connectors?

Impedance matching, typically 50 Ω or 75 Ω, ensures minimal signal reflection and optimal performance.

QWhat materials are used in coaxial connectors?

QWhat materials are used in coaxial connectors?

Materials like brass, stainless steel, and gold plating are used for durability and conductivity.

QHow are connectors attached to cables?

QHow are connectors attached to cables?

Connectors can be soldered, crimped, or tightened onto cables, depending on the design.

QWhat is a reverse-type connector?

QWhat is a reverse-type connector?

In reverse type connectors, the male and female contacts are swapped compared to standard configurations.

QWhat are the benefits of using Tyclon connectors?

QWhat are the benefits of using Tyclon connectors?

Tyclon offers high-quality, customizable connectors with fast delivery, making them suitable for a variety of applications.

QHow can I select the correct connector for my application?

QHow can I select the correct connector for my application?

Consider factors such as frequency range, impedance, environmental conditions, and mechanical requirements when selecting a connector.

QHow can I order coaxial cables, and what support do you offer?

QHow can I order coaxial cables, and what support do you offer?

Ordering is simple—you can purchase our coaxial cables directly on our website or contact our sales team for assistance. We also provide full technical support, including datasheets, CAD models, and application notes, to help you pick the perfect connector for your project.