How to Make a BNC Cable Using Crimp Connectors

Summary

BNC cables consist of a coaxial cable fitted with BNC connectors, providing a robust and reliable connection often used for video and RF signal transmission.

While several methods exist for attaching these connectors, two are most prevalent: the solder and clamp method, and the crimp method.

In this guide, we will focus on the latter crimping method and provide a detailed step-by-step walkthrough on how to assemble a BNC cable using crimp connectors.

Below are the step-by-step instructions for attaching a BNC connector:

1. Crimp the cable’s inner conductor (core) to the center contact of the connector.

2. Place the connector body over the cable’s outer jacket and firmly crimp the crimp sleeve in place.

Benefits of Soldering and Clamping BNC Connectors

Lightweight and Affordable Connectors

After purchasing a crimping tool, you can keep costs low.

Easy Installation

Soldering can be difficult and time-consuming during on-site work, so crimping is recommended.

Work Procedure

Instructions for fabricating a crimp-type BNC cable are provided below.

The steps may vary depending on the product, but BNCP-58A-K is used as a representative example.

Cable mounting diagrams can be downloaded from the website for all products.

Please refer to “View Datasheet” on the product details page.

Cut the cable

Strip the cable

Crimp the center contact

Crimp the connector body

Conduct continuity and insulation resistance checks

Cut the cable

Cut the cable to the specified length. The key point to pay attention to here is the “cut length.”

Even if the total length of the cable is the same, the “cut length” required will vary depending on the reference point for the overall length and the internal dimensions of the connector.

When the total cable length is short, or when the cable is used for measurement applications, precise cut lengths are especially important.

・ If the total length is specified from the tip of the connector: The cut length will be shorter than the total length.

・ If the total length is specified from the base of the connector: The cut length will be longer than the total length.

Trivia: Automatic Cable Cutting Machines

Although cable cutting is often performed manually using cutters, it can also be done with an automatic cable cutting machine.

At Tyclon, we use the “MultiStrip 9480” by Schleuniger, which allows us to cut cables quickly and accurately.

This machine is also capable of performing the subsequent “cable stripping” process automatically.

Strip the cable

Pass the crimp sleeve onto the cable, then cut the insulator, outer conductor (braid), and outer jacket (sheath) according to the cable preparation diagram.

When stripping the cable, make sure to follow the dimensions specified in the installation manual. If using a cutter, you may mark the cut points with a marker.

Trivia: Cable Stripping Devices

Cable stripping is often done using a cutter or similar tool. On job sites, portable and simple strippers are also highly valued for their convenience.

At Tyclon, we use the "Coax Strip 5300" and "Coax Strip 5500" from Schleuniger.

By registering the strip dimensions, we can repeatedly cut cables to the same exact size, ensuring quick and precise cable stripping every time.

Crimp the center contact

Attach the center contact to the inner conductor (core wire), and crimp it using section B of the crimping tool. Be careful not to leave any gaps between the insulators, and do not crimp the flange part of the center contact.

The crimp height at the measuring position differs for each crimping tool:

TA-34: 1.84 mm to 1.97 mm

TA-35: 1.70 mm to 1.74 mm

The measuring position also depends on the crimping tool. For the TA-35, please adjust so that the dimension (A + B)/2 satisfies the value specified above.

Trivia: Crimp Height

In connector assembly, "crimp height" refers to the diameter (height) of the center contact or sleeve after crimping.

Even if you use the same crimping tool and the same dial setting, the crimp height can vary due to tool wear over time or differences in technique.

For this reason, Tyclon's cable preparation diagrams do not specify the crimping tool's strength adjustment dial value.

It is best to follow the procedure shown below and determine the optimal dial setting for the day’s work.

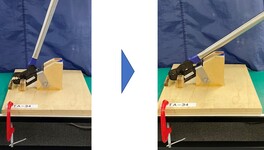

Crimp the connector body

Attach the shell so that it fits between the insulator and the outer conductor (braid) of the coaxial cable.

When the center contact is properly seated, you will hear a clicking sound.

Slide the crimp sleeve over the outer conductor, then crimp it using section A of the crimping tool.

The crimp height at the measurement position should be 6.10 to 6.13 mm. As previously mentioned, please adjust the strength adjustment dial so that it fits within the specified crimp height range.

Be careful not to let the frame or screw part of the crimping tool come into contact with the connector.

Trivia: Using a Crimping Jig

A significant amount of force is required to crimp the sleeve onto the connector body. At Tyclon, we have developed a dedicated jig for use with the crimping tool, which helps improve both work efficiency and accuracy.

Perform continuity and insulation resistance checks

All Tyclon cable assemblies undergo continuity and insulation resistance testing with a tester after completion.

This process helps detect issues such as internal wire breaks or soldering mistakes that cannot be identified through visual inspection.

Only products that have passed other in-house inspection criteria are shipped.

FAQs

QIs custom cable assembly available?

QIs custom cable assembly available?

Yes, we can manufacture custom cables according to your requirements. Please let us know your specifications or needs via the inquiry form.

QDo you offer lead-free connectors?

QDo you offer lead-free connectors?

Yes, we provide lead-free connectors made with GloBrass® (lead-free free-cutting brass) from Mitsubishi Materials. For more details, please refer to the Lead Free Connectors page.

View More

QWhat is your product inspection process?

QWhat is your product inspection process?

All finished products undergo 100% continuity and insulation resistance testing. Only products that have passed all in-house inspection criteria are shipped.

QCan you tighten fasteners to a specified torque?

QCan you tighten fasteners to a specified torque?

Yes, we can accommodate specific torque requirements. Please specify this in your order if needed.

QCan you handle large-volume orders?

QCan you handle large-volume orders?

Yes, we can handle large-volume orders. Please contact us to discuss lead times.

Q Is it possible to request product samples?

Q Is it possible to request product samples?

Sample availability depends on the specific case. Please contact us via the inquiry form for details.