How to Make a N Cable Using Solder and Crimp Connectors

Summary

N-type cables use coaxial cable with N-type connectors, often found in radio communication equipment, especially in the UHF band. While various attachment methods exist, soldering and clamping—or a mix of soldering and crimping—are most common. This guide covers the former, offering a step-by-step walkthrough for assembling an N-type cable using soldering and crimping.

There are two main steps to attach a N connector:

1. Solder the cable's inner conductor (core) to the center contact of the connector.

2. Slide the connector body over the cable’s outer jacket and securely crimp the sleeve in place.

We will explain these in further detail below.

Alternatively, if you were looking for the procedure for using solder and clamp connectors, please see our other guide:

Benefits of Soldering and Crimping N Connectors

Lightweight and Affordable Connectors

Buying a crimping tool lets you save money over time by avoiding repeated labor or assembly costs whenever you need to prepare or repair your own cables.

Work Procedure

Below are the instructions for fabricating a solder-and-crimp type N cable. While steps may differ by product, NP-58/A is used as an example. Cable mounting diagrams for all products are available for download on the website under “View Datasheet” on the product details page.

Cut the Cable

Strip the Cable

Solder the Center Contact

Crimp the Connector Body

Check Continuity and Insulation Resistance

Cut the Cable

Cut the cable to the required length, keeping in mind the "cut length." This is crucial, as the required cut length may differ based on the reference point for the overall length and the connector's internal dimensions. When the cable length is short or used in measurement applications, precision is especially important.

・If the total length is measured from the tip of the connector, the cut length will be shorter.

・If the total length is measured from the base of the connector, the cut length will be longer.

Trivia: Automated Cable Cutters

While cable cutting is typically done manually with cutters, it can also be automated with a cable cutting machine. At Tyclon, we use the “MultiStrip 9480” by Schleuniger, which enables fast and precise cuts. This machine also automates the subsequent “cable stripping” process.

Strip the Cable

Slide the crimp sleeve onto the cable, then cut the insulator, braid, and outer jacket as shown in the cable preparation diagram.When stripping the cable, follow the dimensions in the installation manual. If using a cutter, you can mark the cut points with a marker.

Trivia: Cable Stripping Devices

Cable stripping is typically done with a cutter or similar tool. On job sites, portable and simple strippers are also prized for their convenience. At Tyclon, we use the Coax Strip 5300 and Coax Strip 5500 from Schleuniger. By registering the strip dimensions, we can consistently cut cables to the same exact size, ensuring quick and precise stripping every time.

Solder the Center Contact

Attach the center contact to the inner conductor (core wire) and solder it securely. Ensure the solder does not bulge and there are no gaps between the center contact and the insulator. Soldering requires precision to avoid defects like "cold solder joints," which can occur from excessive solder, high or low temperatures. These defects can cause trapped air or rough surfaces.

At Tyclon, we conduct an internal soldering test, and our skilled technicians perform careful soldering. Afterward, the contact is pulled with radio pliers (about 1 kg of force) to ensure no issues. We also use dedicated jigs to hold parts in place for precise and stable soldering.

Trivia: Pre-Soldering (Tinning)

At Tyclon, we sometimes pre-solder (tin) the inner conductor (core wire) before soldering the center contact. While not always necessary, this step helps create a stronger connection, especially for thick cables or cables with stranded inner conductors, where soldering only at the contact could lead to a weak bond.

Pre-soldering makes it easier for the solder to bond, resulting in a more reliable connection. We use Hakko's FX-300 solder pot to thoroughly tin the inner conductor by soaking it in solder.

Trivia: Lead-Free

At Tyclon, we use lead-free solder in all our cable assemblies. While our standard connectors contain lead, the RoHS directive permits up to 40,000 ppm of lead content. As global environmental regulations on lead tighten, Tyclon has developed lead-free connectors made with Mitsubishi Materials' GloBrass®—a lead-free, free-cutting brass. These lead-free connectors are available as custom-order products.

Crimp the Connector Body

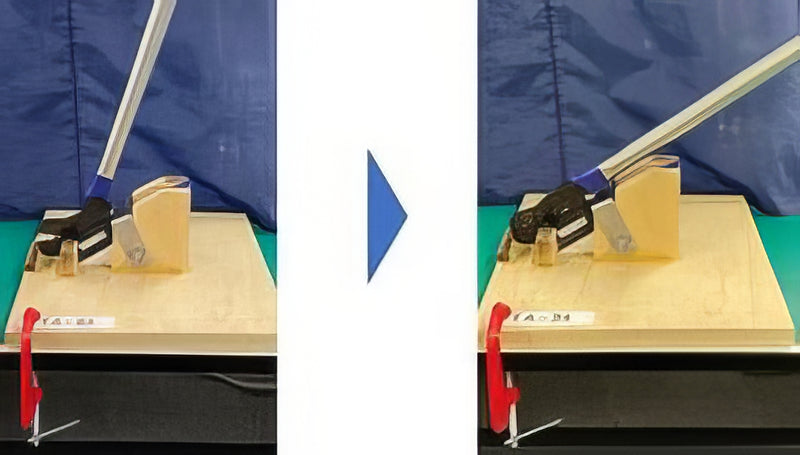

Attach the shell so it fits between the insulator and outer conductor (braid) of the coaxial cable.When the center contact is fully seated, you will hear a click.Slide the crimp sleeve over the outer conductor and crimp it using section A of the crimping tool.

The crimp height should be 6.10 to 6.13 mm. Adjust the dial as needed.Avoid contact between the tool’s frame or screw and the connector.

Trivia: Using a Crimp Jig

Crimping the sleeve onto the connector body requires significant force. At Tyclon, we use a custom jig with the crimping tool to improve both efficiency and accuracy.

Check Continuity and Insulation Resistance

All Tyclon cable assemblies undergo continuity and insulation resistance testing after completion. This process helps detect issues like internal wire breaks or soldering mistakes that can't be seen visually. Only products that pass all in-house inspection criteria are shipped.

N Cable Using Solder and Clamp Connectors FAQs

QIs custom cable assembly available?

QIs custom cable assembly available?

Yes, we can manufacture custom cables according to your specific requirements. Please submit your specifications or needs through the inquiry form.

QDo you offer lead-free connectors?

QDo you offer lead-free connectors?

Yes, we offer lead-free connectors made with GloBrass® (lead-free free-cutting brass) from Mitsubishi Materials. For further details, please visit the [**Lead Free Connectors page**](https://tyclon.com/pages/lead-free-connectors)

Lead Free Connectors page

QWhat is your product inspection process?

QWhat is your product inspection process?

All finished products undergo rigorous 100% continuity and insulation resistance testing. Only items that meet all in-house inspection criteria are shipped.

QCan you handle large-volume orders?

QCan you handle large-volume orders?

Yes, we can accommodate large-volume orders. Please contact us directly to discuss lead times and specific requirements for your order.

Q Is it possible to request product samples?

Q Is it possible to request product samples?

Sample availability depends on the specific case. To inquire about samples, please contact us via the inquiry form for more details and availability.

QDo your N connectors support outdoor use?

QDo your N connectors support outdoor use?

Yes, our N connectors (both 50 Ω and 75 Ω) are designed with robust, weather‑resistant construction for outdoor use, commonly seen in mobile base stations. Please specify environmental requirements when ordering.

QCan you assist with selecting the right connector for my cable?

QCan you assist with selecting the right connector for my cable?

Yes, our technical team can help you select the appropriate N connector based on your cable type, application, and performance needs.